What are packaging boxes made of?

Packaging boxes are made of corrugated board (as known as corrugated boxes) which are composed of two main elements:

Both of these elements are made from the same material such as container board:

1. Corrugated Medium: Center fluted (corrugated) material

2. Liner-board: The flat sheets of paper which are glued to the medium

Types of Papers

There are two main types of paperboard: Kraft and Test.

Kraft Paper : The strongest form of paper and the best to print on this is the most common outside liner for corrugated boxes.

Test Paper : Also named as double layer paperboard “Duplex Paper”. Most standard cartons use recycled paper for the fluting and the inside liner.

Types of Corrugated Walls

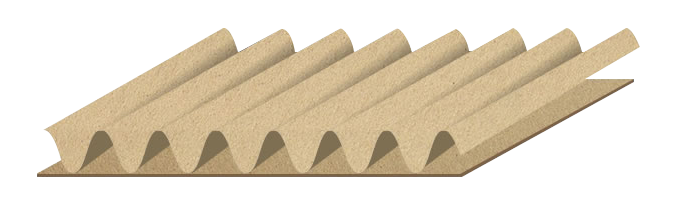

• Single Face Board

Doesn’t have the durability that other types of corrugated packaging materials have, but is very cheap to produce and can provide an extra layer of protection to already packaged products.

• Single Wall Board

The most common style corrugated cardboard is manufactured in. It simply consists of 1 layer of whatever flute type you choose.

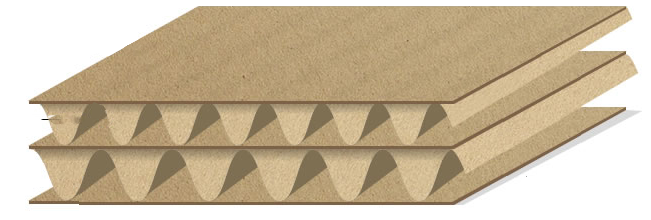

• Double Wall Board

A corrugated board construction where two layers of medium are glued between three layers of flat liner-board facing.

Much more resistant to breaking when stacked. This type of corrugated is commonly used for large industrial containers.

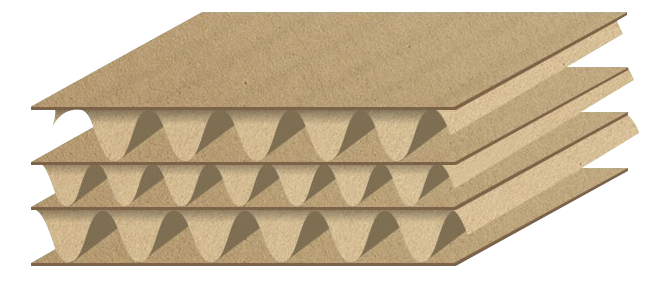

• Triple Wall Board

Strong enough to be a substitute for wooden crates. It has traditionally been used for shipping chemical containers.

Corrugated Box Flute Types

Common flute sizes are “A”, “B”, “C”, “E”, “F” or micro flute.

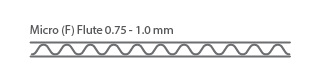

• Micro (F) Flute

Has excellent printing surface. Typically used for high quality shelf ready packaging such as boxes for cosmetics, jewelry and shoes.

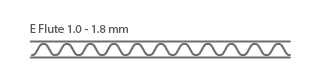

• E Flute

Has excellent crush resistance, exceptional printing surface and compression strength. Commonly used in consumer goods packaging (smaller cartons) such as boxes for cosmetics, glass and ceramics.

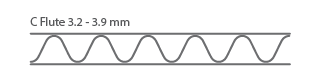

• C Flute

Has excellent compression strength. Slightly better stacking strength for lighter products. Most commonly used for glass, furniture and food etc.

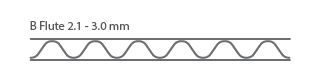

• B Flute

Most common type of fluting for packaging boxes with excellent crush resistance, printing surface and puncture resistance. Almost seen in all types of applications.

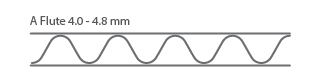

• A Flute

Is the original corrugated flute design and is the thickest. With its thickness, A-flute provides the greatest cushioning properties for fragile products. A-flute offers excellent stiffness qualities and short column crush resistance.

What are advantages of corrugated board?

♦ Economical and lightweight

♦ 100% recyclable

♦ Allows printing surface

♦ Different designs available regarding to have different packaging properties such as excellent printing surface, crush resistance

♦ Enables easy storage and handling